We are currently still building up the English documentation; not all sections have been translated yet. Please note that there may still be German screenshots or links to German pages even on pages that have already been translated. This guide mostly addresses English speaking users in Germany.

Video

EazyShipping

In this video we explain the goods issue with EazyShipping in JTL-WMS.

Goods issue with EazyShipping

The EazyShipping process offers the possibility to efficiently pick sales orders with collective picking and to pack them directly (without shipping boxes) at the packing bench.

Process description

With EazyShipping, a route-optimised pick list is created and printed out at the touch of a button. On this pick list, the employee sees from which storage location they can pick which item in which quantity. The items are collected on a picking trolley. There is no sorting by sales orders on this trolley. This process is called collective picking.

Using JTL-WMS Mobile: Collective picking can also be carried out with JTL-WMS Mobile. This makes picking easier because the employee is guided to the individual storage locations in a route-optimised manner. Among other things, employees are also shown item images, which facilitates picking. By scanning the item’s bar code, the quantity is posted directly to the picking trolley. That way, the stock level in JTL-WMS always corresponds to the actual stocks. With collective picking with slips of paper and without JTL-WMS Mobile, the posting of removing the stock from the storage location is not communicated to JTL-WMS until much later. In addition, when using JTL-WMS Mobile, you can immediately record shortages or wrong stock levels and correct them.

After the pick list has been completed, all required items should be on the picking trolley. Take the trolley to the packing bench. Start the packing process by opening the EazyShipping dialogue in JTL-WMS. Take any item from the trolley and scan the bar code. JTL-WMS identifies the corresponding sales order. If there is only that one item in the sales order, the invoice, delivery note and shipping label can be printed directly. If the shipping methods are preset correctly, then scanning the item if sufficient to trigger the printing process. The complete sales order can therefore be sent, printed and reported in just one scan!

If there are more items that belong to the sales order, these must also be processed and packed. Therefore JTL-WMS shows you which items are still missing. Take the respective items from the picking trolley and scan them. While this process is great for some setups, it might not be the best choice for others.

Below you will find two examples for one good and one bad setup for sales orders with more than one item.

Advantages

Disadvantages

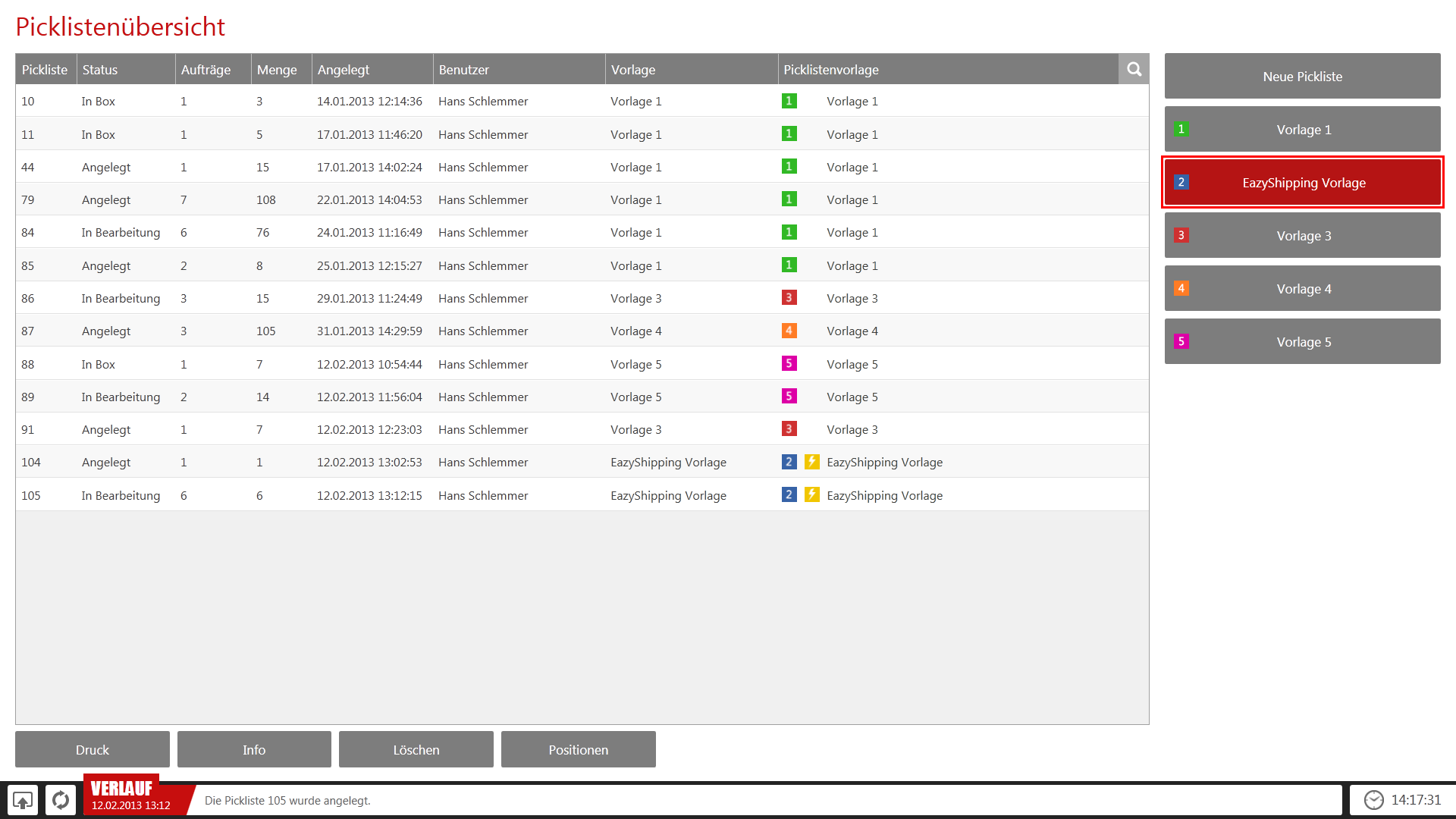

Creating pick lists

You need to create EazyShipping pick lists to process orders with EazyShipping. Pick lists bundle several sales orders to enable route-optimised picking.

You will find all important information on this here:

Picking items

In the EazyShipping process, picking can be done with or without JTL-WMS Mobile. If you do not work with a PDT, retrieve the goods from the warehouse using the printed pick list. If you are working with PDT, call up the collective picking dialogue.

Regardless of the use of JTL-WMS Mobile, at the end of the picking process, all items are on a picking trolley and are taken to the packing bench.

Packing

The EazyShipping pick lists picked in collective picking are packed in JTL-WMS in the EazyShipping dialogue.

Packing directly from goods receipt using EazyShipping

Video

EazyShipping

In this video we explain the goods issue with EazyShipping in JTL-WMS.