We are currently still building up the English documentation; not all sections have been translated yet. Please note that there may still be German screenshots or links to German pages even on pages that have already been translated. This guide mostly addresses English speaking users in Germany.

Goods issue: Collective picking

Your task/initial situation

With collective picking, all sales order line items of a pick list are collected on a picking trolley. All items are mixed on the picking trolley and will be sorted by sales order later on during the following processes:

Requirements

How to start picking

- Start JTL-WMS Mobile.

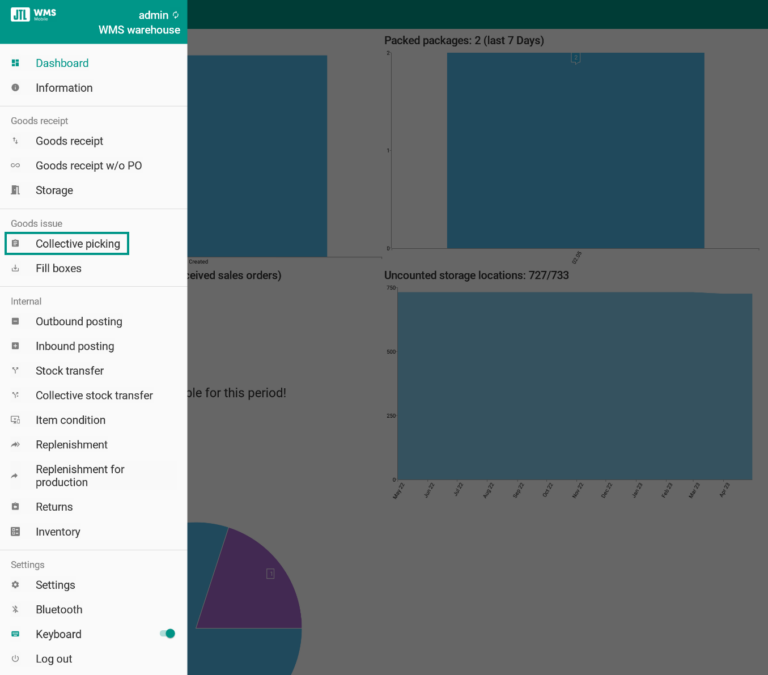

- Open the hamburger menu and select the Collective picking menu item.

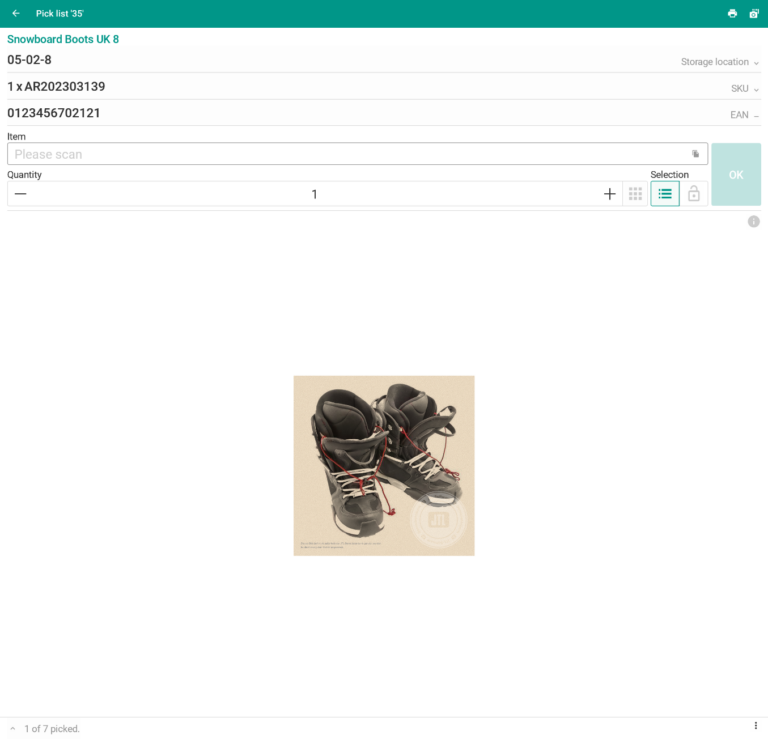

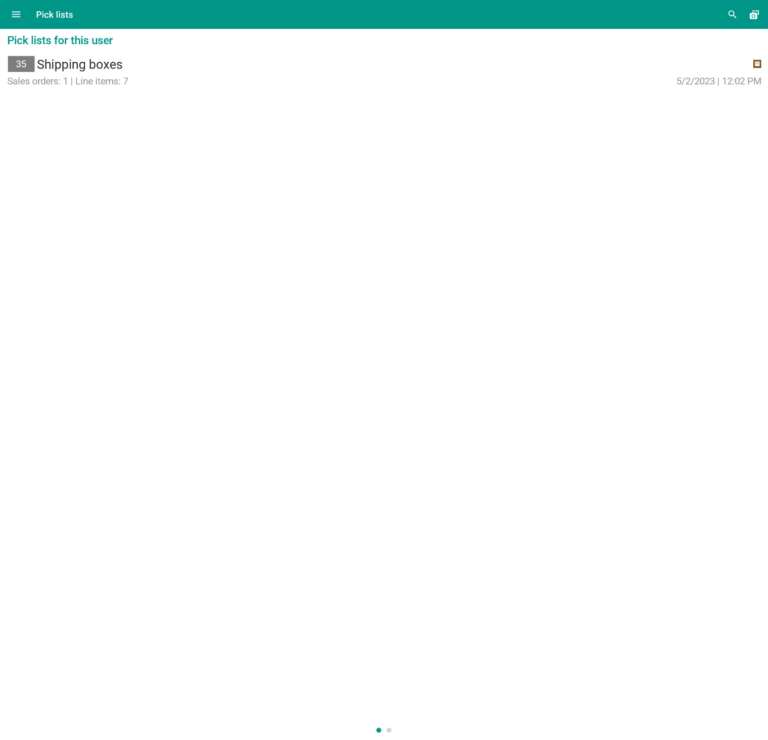

- Select your pick list from the list or search for it using the search field. You can also create a new pick list using the + button. You will then be taken to the individual storage locations of the pick list in a route-optimised manner.

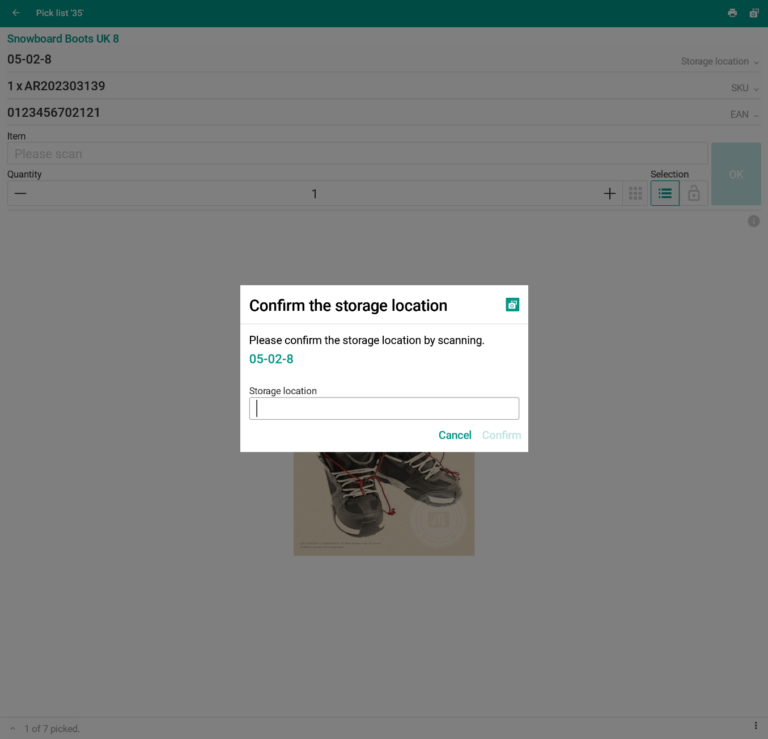

- Scan the storage location from which you want to take out the items. This confirmation is only required if you have activated the Confirming the storage location check box in JTL-Wawi in your storage settings under JTL-WMS Mobile tab > Picking.

- Now scan the items that you want to take out of this storage location.

- Repeat until the pick list is complete. When the pick list has been completed, you can go back to the main menu and process the next pick list.

Filling boxes

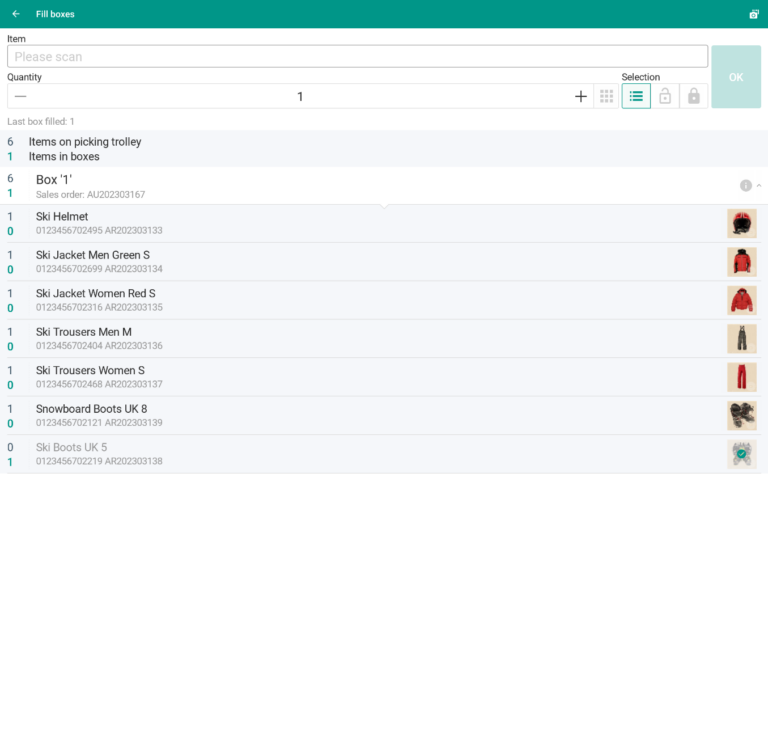

After the pick list has been processed, you must sort the items on the picking trolley. This can be done via the Fill boxes menu item. Below you will find instructions on how to do this.

- Start JTL-WMS Mobile.

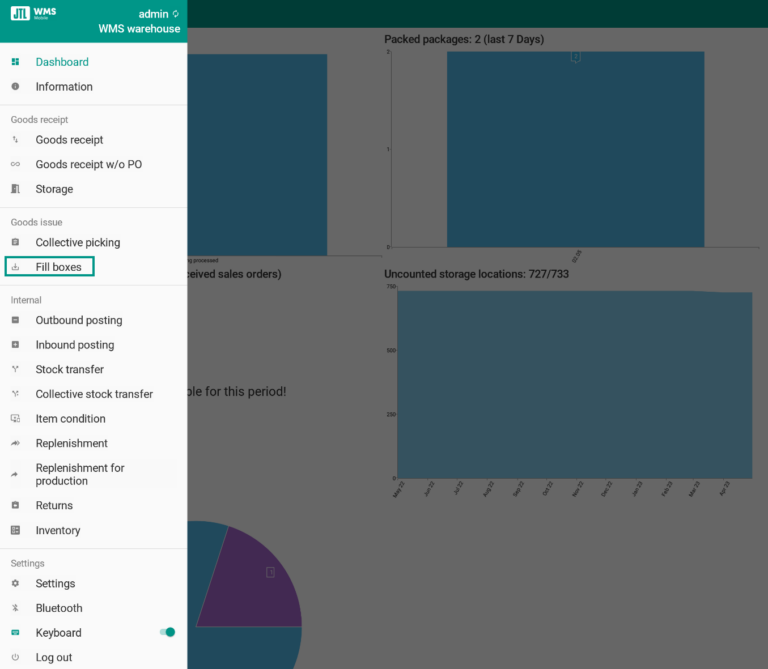

- Open the hamburger menu and select the Fill boxes menu item.

- Select your pick list from the list or search for it using the search field.

- Scan an item or select the item from the list.

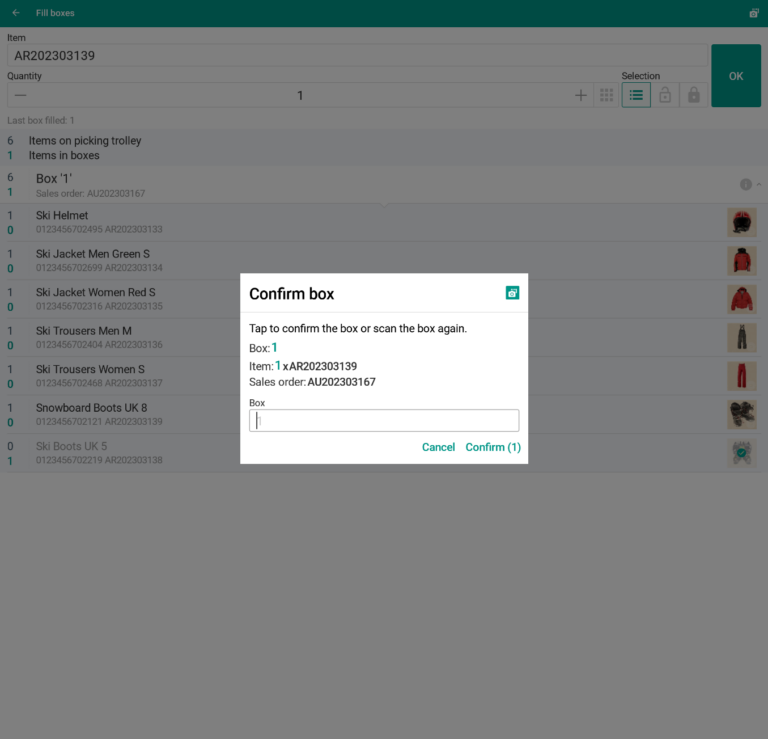

- Now put the item into the displayed shipping box and then scan the shipping box.

- Repeat until all items are assigned to the shipping boxes. When the pick list has been completed, you can go back to the main menu and process the next pick list.

Special cases

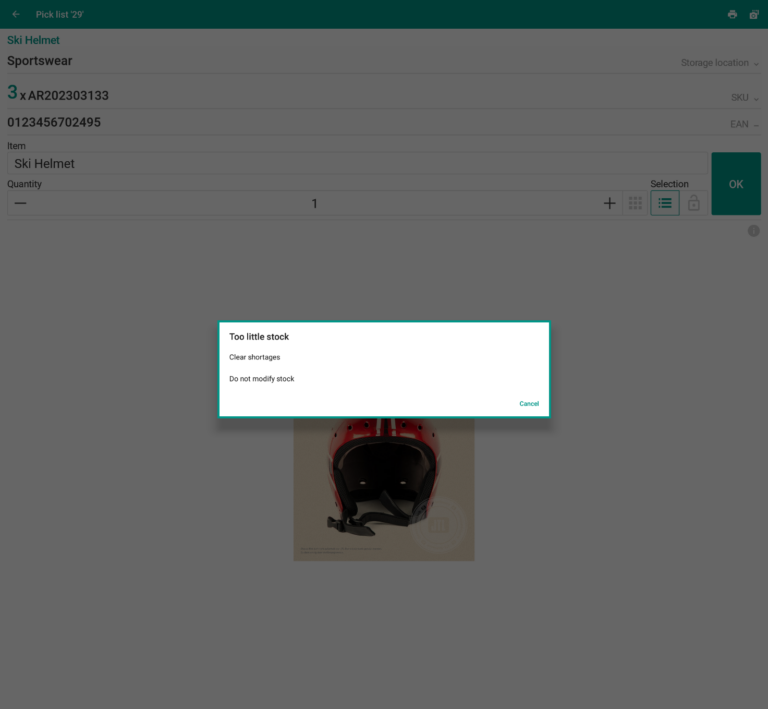

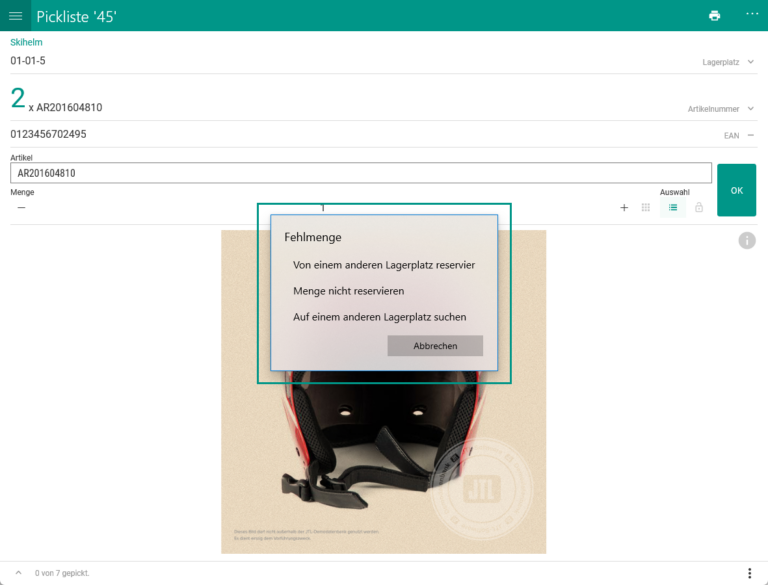

Dialogue: Too little stock

Sometimes the user can only take a smaller amount from the storage location during picking than required (shortage in the storage location). Whenever an insufficient amount is entered during picking, the user is asked two questions. By answering the first question, you specify what to do about the missing stock. Do you want to clear it or do you not want to modify the stock? The following buttons are displayed to the user:

Dialogue: Shortage

If you click one of these buttons, you must choose what happens to the line item on the pick list for which there is no available stock. You can either reserve from another storage location or delete the pick list line item.