We are currently still building up the English documentation; not all sections have been translated yet. Please note that there may still be German screenshots or links to German pages even on pages that have already been translated. This guide mostly addresses English speaking users in Germany.

Purchase order proposals

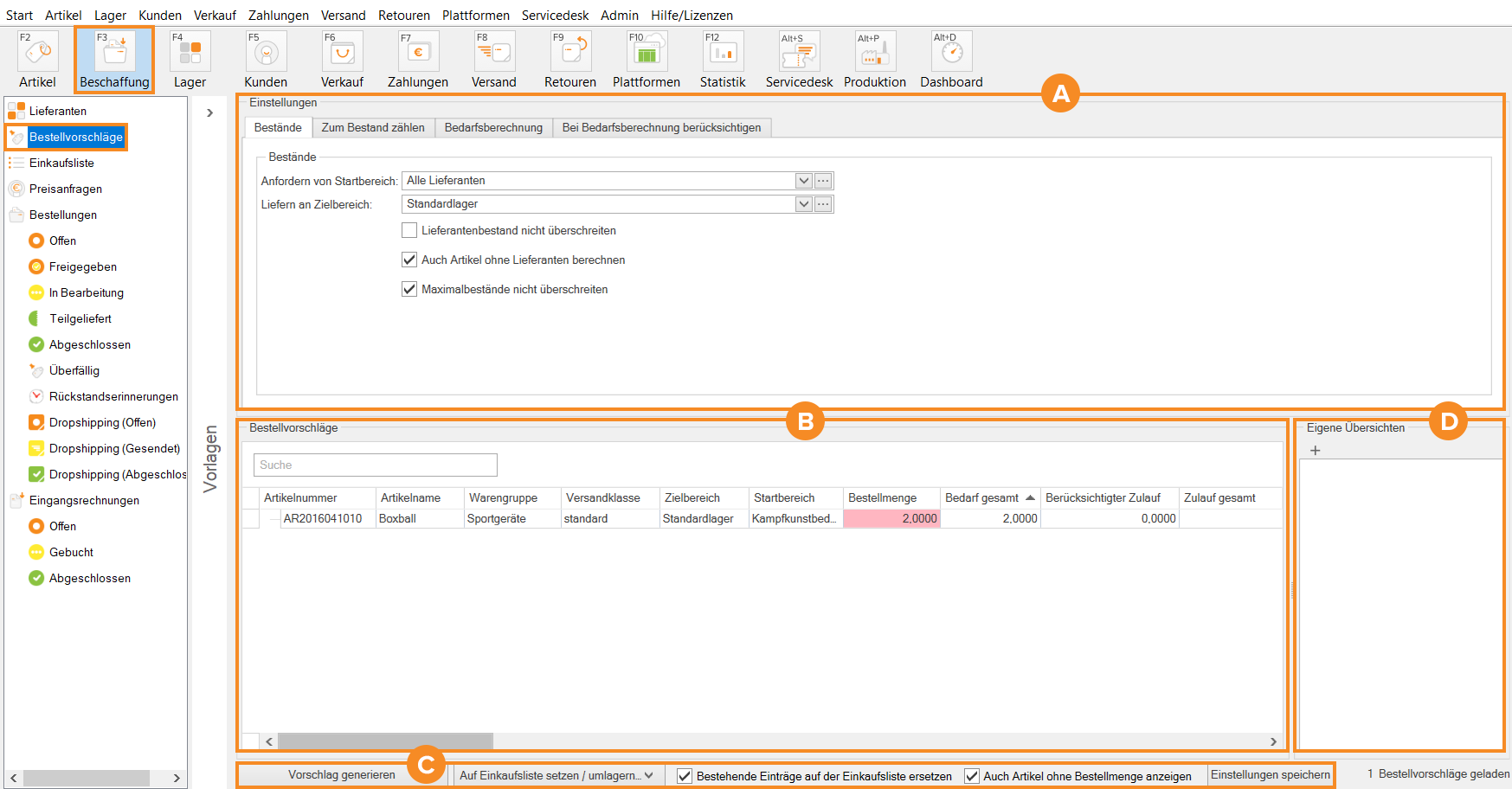

On this page you will find a detailed description of all functions of the purchase order proposal. You call it up by clicking on the Procurement icon in JTL-Wawi and selecting Purchase order proposals in the category structure.

General information on purchase order proposals

With the help of purchase order proposals, you can determine your probable future demand and optimally replenish your stock. You can configure the calculation of purchase order proposals according to your requirements and separately take into account criteria such as specific time periods, sales orders or quantities on the purchase list.

Watch the video JTL-Wawi purchase order proposals – Basics for sellers.

Pane A: Settings

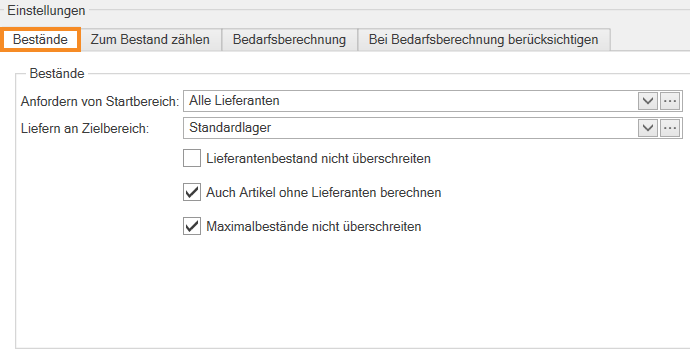

Stocks tab

Anfordern von Startbereich: In diesem Dropdown-Menü können Sie Lieferanten bzw. Warenlager wählen, bei denen JTL-Wawi Ware nachbestellen soll. Sehen Sie sich hierzu auch das Video JTL-Wawi Bestellvorschlag – Start- und Zielbereich an. Wie Sie einen Startbereich anlegen und Ihren Anforderungen entsprechend konfigurieren, lesen Sie hier: Bestellvorschläge generieren.

Destination area: In this drop-down menu, select the warehouse for which JTL-Wawi should determine the probable future demand. You can also select WMS storage sections and WMS storage locations. Also watch the video JTL-Wawi purchase order proposals – start and destination area. Read here how to create a destination area: Generating purchase order proposals.

Do not exceed supplier stocks: Activate this check box to specify that JTL-Wawi orders only a quantity from each supplier that is actually in stock and orders from different suppliers according to the supplier prioritization until the required quantity is reached.

Also calculate items without supplier: Activate this check box to specify that items that do not have a supplier are also displayed.

Do not exceed maximum stocks: Activate this check box to specify that the quantity of items ordered does not exceed the maximum stocks as specified in the item master data.

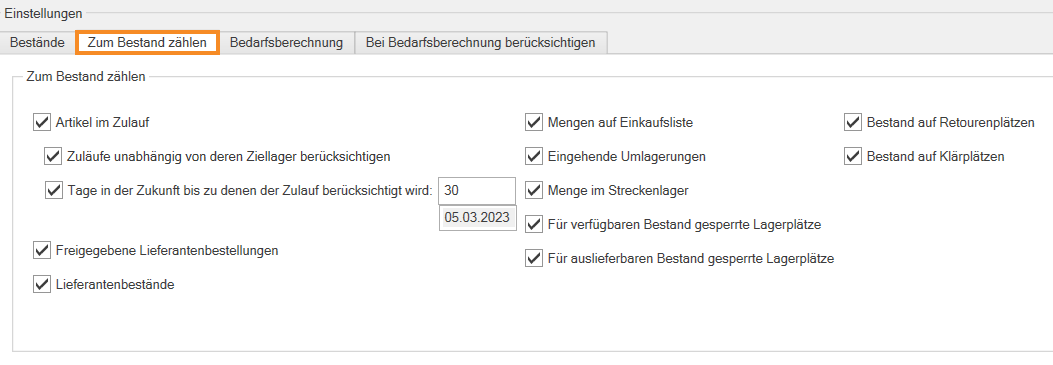

Count as stock tab

Items awaiting delivery: The quantity of items awaiting delivery are considered stock in the calculation.

Zuläufe unabhängig von deren Ziellager berücksichtigen: Positionen, die sich im Zulauf befinden, werden unabhängig vom Ziellager berücksichtigt.

Tage in der Zukunft bis zu denen der Zulauf berücksichtigt wird: In diesem Feld können Sie ein Datum in der Zukunft festlegen, bis zu dem der Zulauf berücksichtigt werden soll. Sie können ebenfalls einen relativen Zeitraum, wie beispielsweise 30 Tage, angeben.

Authorised purchase orders: Purchase orders that have not yet been placed but have already been authorised are included in the stock calculation.

Supplier stocks: Supplier stocks of supplier items where the check box Add to own stock has been activated are included as stock in the calculation.

Quantity on purchase list: Quantities that are already on purchase lists, for example due to a purchase order proposal, are included in the stock calculation.

Inbound stock transfers: Goods that will be received due to a stock transfer are included in the stock calculation.

Menge im Streckenlager: Ware, die sich im Streckenlager, also auf dem Weg ins Ziellager, befindet, wird bei der Berechnung als Bestand berücksichtigt.

Storage locations blocked for available stock: Stocks that are located in warehouses or storage locations and are blocked for the available stock, i.e. are not offered for sale, are counted as stock. For more information on this topic, click here: Item master data: Stocks overview.

Storage locations blocked for deliverable stock: Stocks that are located in warehouses or in storage locations and are blocked for delivery are counted as stock. For more information on this topic, click here: Lock warehouse for shipment.

Stock in return locations: Stocks that are in return locations are included as stock in the calculation. For more information on this topic, click here: Creating storage locations in JTL-WMS.

Stock in clarification locations: Stocks that are located in clarification locations are included as stock in the calculation. For more information on this topic, click here: Creating storage locations in JTL-WMS.

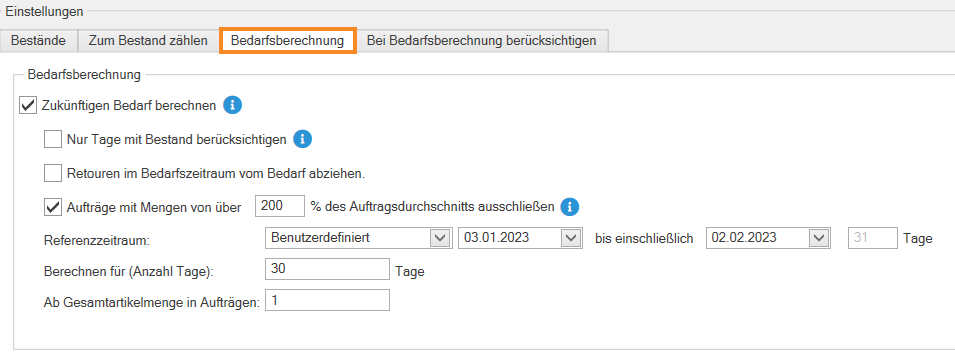

Demand calculation tab

Calculate future demand: Activate this check box if you want to calculate your demand for a certain time period in the future. The future demand is calculated on the basis of the goods issues of all warehouses in the destination area in the selected reference period.

Only consider days with stock: Only days are considered in the calculation on which stock was available at some point. Please note that by activating this option, the calculation can take significantly more time.

Retouren im Bedarfszeitraum vom Bedarf abziehen: Bei der Berechnung werden Retouren des Bedarfszeitraums nicht berücksichtigt.

Aufträge mit Mengen von über X% des Auftragsdurchsschnits ausschließen: Ein Auftragsdurchschnitt aller versendeten Aufträge des Artikels wird für den Referenzzeitraum berechnet. Aufträge, die X Prozent mehr Menge als dieser Durchschnitt haben, werden bei der Berechnung nicht betrachtet.

Referenzzeitraum: Wählen Sie in dem Dropdown-Menü aus, ob Sie einen benutzerdefinierten oder einen relativen Zeitraum angeben möchten. Einen benutzerdefinierten Zeitraum können Sie anschließend über die Datumsfelder definieren.

Calculate for (number of days) X days: Define the number of days in the future for which demand is to be calculated in this field.

Für Artikel mit Bedarf ab: Legen Sie in diesem Feld fest, wieviel Menge eines Artikels mindestens in einem Auftrag sein muss, um im Bestellvorschlag aufgeführt zu werden.

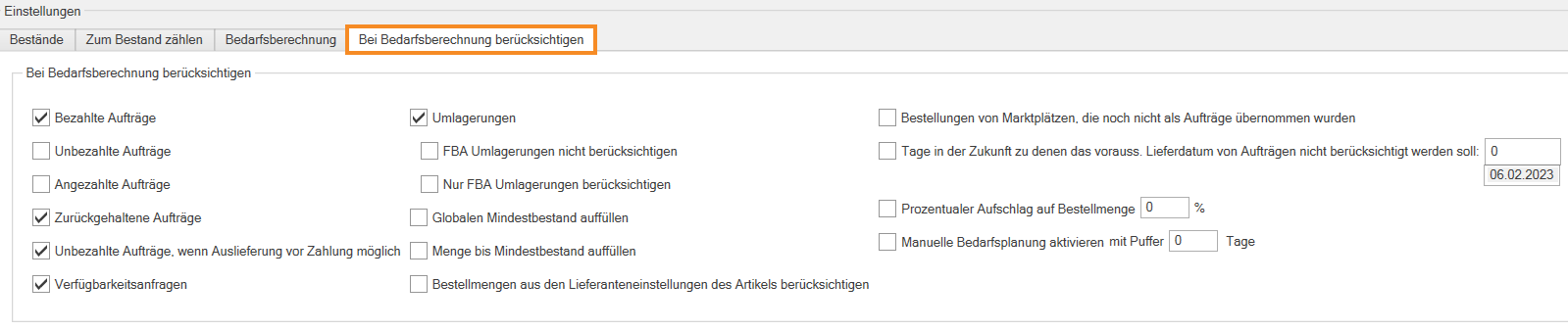

Consider when calculating demand tab

Paid sales orders: Paid orders that have not been shipped are added to the calculated demand.

Unpaid sales orders: Unpaid orders that have not been shipped are added to the calculated demand.

Angezahlte Aufträge: Angezahlte, nicht versendete Aufträge werden zum errechneten Bedarf addiert.

Sales orders on hold: Sales orders that were put on hold, for example because they first need to be checked, are included in the calculation.

Unbezahlte Aufträge, wenn Auslieferung vor Zahlung möglich: Aufträge, deren Zahlung zu einem späteren Zeitpunkt eintrifft, werden zum errechneten Bedarf addiert.

Availability requests: The availability requests for items from your JTL-Shop are added to the calculated demand. For more information on this topic, click here: Managing availability requests.

Umlagerungen: Umlagerungen werden zum errechneten Bedarf addiert.

FBA Umlagerungen nicht berücksichtigen: Umlagerungen, die ein FBA-Lager als Ziel haben, werden nicht zum errechneten Bedarf addiert.

Nur FBA Umlagerungen berücksichtigen: Ausschließlich Umlagerungen, die ein FBA-Lager als Ziel haben, werden zum errechneten Bedarf addiert.

Globalen Mindestbestand auffüllen: Mit dem generierten Bestellvorschlag wird der globale Mindestbestand zum errechneten Bedarf addiert. Lesen Sie mehr zum Thema hier: Mindest- und Maximalbestände pro Lager pflegen und Globalen Mindestbestand für ein Warenlager auffüllen.

Menge bis Mindestbestand auffüllen: Mit dem generierten Bestellvorschlag wird der Mindestbestand je Warenlager aufgefüllt. Lesen Sie mehr zum Thema hier: Mindest- und Maximalbestände pro Lager pflegen.

Consider order quantities in the supplier settings of the item: Minimum order quantities and permissible order quantity of the suppliers selected in the start area are considered.

Order quantities from marketplaces not yet imported as sales orders: Pending orders from marketplaces not yet imported into JTL-Wawi as a sales order are included in the calculation. For more information on this topic, click here: Amazon FAQ.

Tage in der Zukunft zu denen das vorauss. Lieferdatum von Aufträgen nicht berücksichtigt werden soll: Es werden nur Aufträge zum Bedarf gezählt, deren voraussichtliches Lieferdatum vor dem ausgewählten Datum liegt oder bei denen das voraussichtliche Lieferdatum nicht vorhanden ist.

Surcharge in percent for order quantity X%: Enter the percentage value that you want to surcharge for the order quantity.

Enable manual demand planning with buffer X days: Activate this check box to activate the manual demand planning from JTL-Plan&Produce and specify the buffer with which the sales order is to be placed.

Pane B: Purchase order proposals

Here you can see all purchase order proposals configured on the basis of your filter settings (Pane A).

SKU: Shows the SKU.

Item name: Shows the item name.

Product group: Shows the product group.

Shipping class: Shows the shipping class of the item.

Destination area: The warehouse for which JTL-Wawi has determined the probable future demand.

Start area: Shows the supplier from whom the goods are reordered.

Order quantity: Shows which quantity of the item will be ordered. The quantity can be changed manually.

Total demand: Shows the demand calculated by the purchase order proposal, including everything that is added to the demand according to your configuration.

Awaiting delivery (total): Shows the quantity of the item that is already awaiting delivery.

Total stock: Shows the total quantity of the item that is in stock.

Proposed demand: Shows the demand calculated by the purchase order proposal.

Total shortage: Shows the total item quantity that is out of stock. The shortage is calculated as follows: Stock – Open sales orders – Stock blocked for available stock = Shortage.

Minimum stock level: Shows the minimum stock of the warehouses saved for the item.

Maximum stock level: Shows the maximum stock of the warehouses saved for the item.

Available (total): Shows the total available quantity of the item. The available quantity is calculated as follows: Stock – Open sales orders – Stock blocked for available stock = Available (total).

Open sales order quantity: Shows the quantity of the item that is in open sales orders.

Daily demand: Shows the daily demand for an item based on the demand calculation.

Supplier stocks: Shows the stock that is available at the supplier of the item.

Total quantity on purchase list: Shows the total quantity of the item already on the purchase list.

Total demand in time period: Shows the demand of the item in the specified reference period.

Demand/30 days Shows the demand of the item in the last 30 days.

Permissible order quantity: Shows the permissible order quantity specified by the supplier for the item.

Minimum order quantity: Shows the minimum order quantity specified by the supplier for the item.

Demand without sales orders: Shows orders not yet imported as sales orders in JTL-Wawi. This can include pending orders from marketplaces such as Amazon.

Manual demand: Shows the demand of the item without orders. This demand is generated in JTL-Plan&Produce.

Locked for shipment: If the item is locked for shipment, this will be displayed here.

Availability requests: Shows availability requests for the item transferred via JTL-Shop.

MPN: Displays the MPN of the item.

GTIN: Shows the GTIN of the item.

Supplier SKU: If the supplier has a different SKU for this item, it will be displayed here.

Note for supplier: You can enter a note here, which will be included in the purchase list and from there in the purchase order.

Global minimum stock level: Shows the minimum stock level of the item that exists globally. For more information on this topic, click here: Managing minimum and maximum stocks per warehouse.

Pane C: Toolbar

Generate proposal: Click on this button to generate the purchase order proposal.

Only add selected items to purchase list: This option becomes visible when you click on the black arrow on the Add to purchase list button. Only the items that you have selected in the list view are added to the purchase list.

Add all items to purchase list: This option becomes visible when you click on the black arrow on the Add to purchase list button. All items that are in the list view are added to the purchase list.

Replace existing entries on the purchase list: If you activate this option, the quantities on the purchase list are replaced by the quantities calculated in the purchase order proposal. If this option is not activated, the calculated quantity will be added to the existing purchase list.

Also show items without order quantity: If you enable this option, you will be shown items that do not have an order quantity.

Einstellungen speichern: Klicken Sie auf diese Schaltfläche, um die Einstellungen des Bestellvorschlags für den angemeldeten Nutzer zu speichern. Wenn Sie die Einstellungen speichern, können Sie diese zukünftig als Vorlage nutzen.

Pane D: Custom overviews

In the Custom overviews area, you can configure your own overviews using the plus icon and use SQL commands to specify which data is to be displayed in your overview. Read more on the topic here.

Watch the video Purchase order proposals with custom overviews.